Calibration Services for Food Industry in India – NABL Certified & FSSAI-Compliant Solutions

Ensure 100% accuracy, reliability, and compliance in your food testing and processing equipment with India’s leading Calibration Services for the Food Industry by MyFoodExpert.in. We provide NABL-accredited calibration for food lab instruments, processing machinery, weighing scales, thermometers, ovens, pH meters, and more — ensuring your equipment meets FSSAI, ISO 22000, and BIS standards.

With our PAN-India calibration network, food manufacturers, testing laboratories, dairy plants, bakeries, and beverage industries can maintain precision, consistency, and audit-readiness — all under one expert service provider. Whether you run a small food business or a large-scale processing plant, we deliver on-site and in-lab calibration services that meet international quality benchmarks.

Professional Calibration Services to Ensure Food Safety & Compliance

At MyFoodExpert, we specialize in NABL-accredited calibration services for the food industry in India. Accurate and reliable instrument calibration is critical to maintain food safety, quality, and regulatory compliance. Our experts calibrate a wide range of food processing and laboratory equipment, ensuring your operations meet both national and international standards.

What is Calibration in the Food Industry?

Calibration in the food industry is the process of verifying and adjusting the accuracy of instruments and equipment used in food production, testing, and quality control. It ensures that every reading, measurement, and process parameter — such as temperature, pH, weight, pressure, and humidity — is accurate, traceable, and compliant with FSSAI, NABL, ISO 22000, HACCP, and BIS standards.

In simple terms, calibration services confirm that your food equipment performs precisely as per the defined standards. This not only guarantees product safety and consistency but also protects your brand from FSSAI non-compliance, recalls, and audit failures.

At MyFoodExpert, we specialize in providing professional calibration services for food laboratories, manufacturing units, and processing plants across India. Our NABL-accredited calibration helps ensure your devices — from thermometers, pH meters, and weighing balances to ovens, refrigerators, and moisture analyzers — deliver accurate and reproducible results every time.

By maintaining periodic calibration schedules, food businesses can ensure:

- Consistent product quality and safety

- Compliance with national and international food regulations

- Extended equipment life and performance stability

- Smooth FSSAI inspections and ISO audits

Why Choose MyFoodExpert for Calibration Services?

Choosing the right partner for calibration services for the food industry in India is critical to ensure accuracy, compliance, and reliability. At MyFoodExpert, we provide comprehensive, NABL-accredited calibration solutions tailored for food processing, packaging, and laboratory equipment. Here’s why we are the trusted choice for food businesses across India:

1. NABL-Accredited Calibration Services

Our calibration services are fully accredited by NABL, ensuring that all measurements and instruments meet national and international standards. Using NABL-certified procedures guarantees accuracy, compliance, and credibility, which is essential for maintaining food safety standards in your operations.

2. Expertise in Food Industry Calibration

With years of experience in the food sector, our technicians specialize in food lab calibration and instrument calibration for food processing equipment. From weighing scales, thermometers, and pH meters to moisture analyzers and humidity sensors, our experts handle a wide range of equipment with precision and professionalism.

3. Comprehensive Equipment Coverage

We provide end-to-end calibration services for all types of instruments used in the food industry. Whether it’s critical lab testing devices, production line sensors, or custom food processing tools, MyFoodExpert ensures that every piece of equipment is accurately calibrated for optimal performance and regulatory compliance.

4. Ensures Food Safety & Quality Compliance

Accurate calibration is the backbone of food safety and quality assurance. By choosing MyFoodExpert, you can maintain FSSAI, ISO, and HACCP compliance, reduce operational errors, and consistently deliver high-quality, safe products to your customers.

5. Nationwide On-Site and In-Lab Services

We understand the challenges of downtime in food production. That’s why we offer flexible on-site calibration services across India, as well as in-lab calibration options. Our goal is to ensure minimal disruption to your operations while maintaining top-quality calibration results.

6. Precision, Reliability, and Accuracy

Every calibration performed by MyFoodExpert is conducted with state-of-the-art instruments and standardized procedures. Our focus on precision and reliability ensures that your food processing and laboratory equipment consistently delivers accurate results, supporting quality control, product consistency, and operational efficiency.

7. Periodic Calibration & Support

We don’t just calibrate and leave; we offer periodic calibration schedules and technical support to keep your instruments functioning at their best. Regular calibration prevents equipment drift, measurement errors, and compliance risks, safeguarding your business from potential regulatory issues.

8. Trusted by Food Industry Leaders

MyFoodExpert is a preferred partner for food manufacturers, laboratories, and quality control teams across India. Our commitment to accuracy, certification, and client satisfaction has made us a trusted name in food industry calibration services.

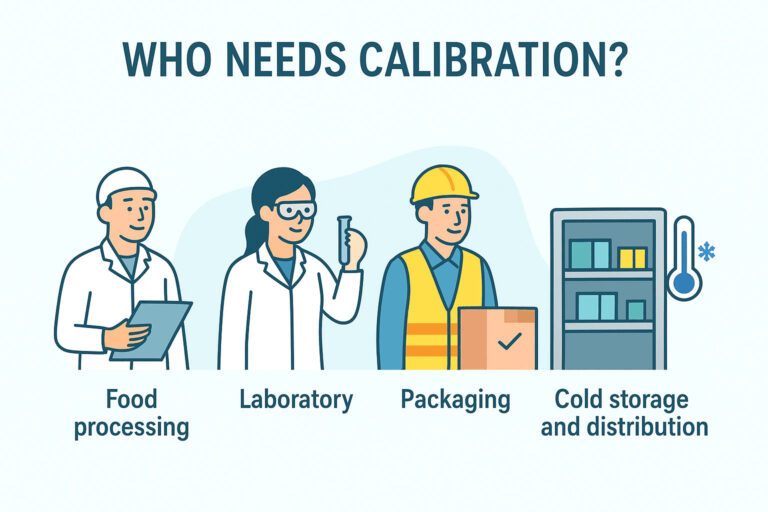

Represents the wide range of industries and professionals that depend on accurate, traceable calibration services to maintain quality and compliance in the food industry in India. It visually connects the essential sectors — food processing lines, testing laboratories, packaging units, and cold storage facilities — all of which require NABL-accredited calibration to ensure precision, safety, and consistency.

Calibration is a critical part of FSSAI and ISO 22000 compliance, ensuring that measuring instruments such as weighing scales, temperature sensors, pH meters, and flow meters deliver reliable data for food production and testing. Through this illustration, MyFoodExpert emphasizes that every stakeholder in the food value chain — from manufacturers to lab analysts — benefits from regular, certified calibration services that guarantee traceability, reduced uncertainty, and audit-ready documentation.

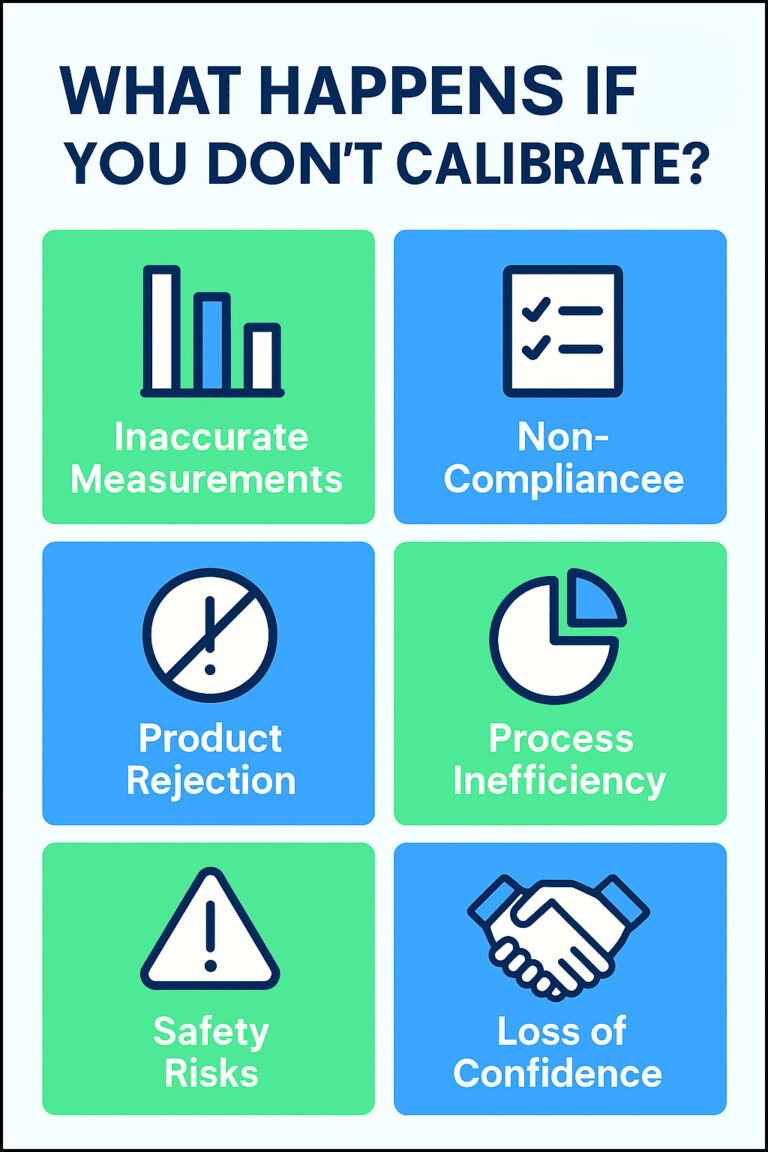

What Are the Consequences of Not Performing Calibration?

Skipping or delaying instrument calibration can lead to serious consequences for food businesses, including compliance failures, inaccurate results, and product quality issues. In the food industry, where precision directly affects safety and consumer trust, the risks are even higher.

1. Inaccurate Measurements

Without calibration, weighing scales, thermometers, pH meters, and flow meters can drift from true values. This results in incorrect ingredient ratios, temperature deviations, and measurement errors, leading to inconsistent or unsafe food products.

2. Non-Compliance with FSSAI, ISO 22000, and NABL

Uncalibrated instruments violate FSSAI and ISO 22000 requirements for measurement traceability. During audits, lack of valid NABL-traceable calibration certificates can result in non-compliance reports, penalties, or suspension of certification.

3. Product Rejection and Recalls

When measurements are inaccurate, batches may fail quality checks, forcing product rework or recalls. This leads to financial losses, waste of raw materials, and potential damage to your brand reputation.

4. Process Inefficiency and Increased Costs

Drifting instruments can cause overuse or underuse of ingredients, energy, and time, reducing operational efficiency. Regular calibration prevents process variability and helps maintain cost control and production consistency.

5. Safety Risks and Legal Liability

In food processing, even a small temperature or pressure error can compromise food safety, leading to contamination or spoilage. Failing to calibrate instruments exposes your business to legal risks, regulatory action, and customer safety issues.

6. Loss of Customer and Audit Confidence

When calibration is neglected, traceability and data integrity are compromised. Auditors, clients, and consumers lose confidence in your testing results and product reliability, impacting long-term business relationships.

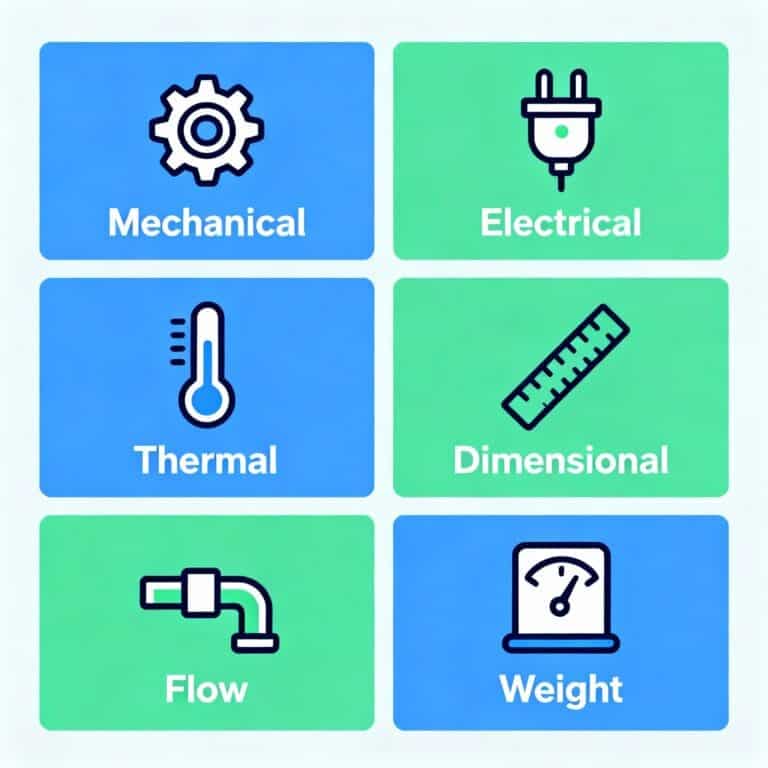

Types of Calibration Services?

At MyFoodExpert, we provide comprehensive calibration services for the food industry in India, covering all key equipment categories to ensure accuracy, traceability, and compliance with NABL standards.

Mechanical Calibration

We perform mechanical calibration for instruments that measure force, torque, mass, vibration, and dimensions. Equipment such as calipers, micrometers, torque wrenches, and load cells are verified against traceable mechanical standards, ensuring audit-ready accuracy and compliance for food industry applications.

Electrical Calibration

Our electrical calibration services validate instruments like multimeters, oscilloscopes, and signal generators. Each device is compared to high-accuracy electrical references, ensuring reliable data, minimized uncertainty, and consistent equipment performance across food testing and processing operations.

Thermal Calibration

We specialize in thermal calibration of thermometers, thermocouples, RTDs, infrared sensors, ovens, and temperature chambers. Each instrument is tested in controlled reference baths or dry-blocks to guarantee precise temperature monitoring essential for food safety and thermal process control.

Dimensional Calibration

Our dimensional calibration services ensure accurate length, angle, and geometry measurements for critical tools like vernier calipers, gauge blocks, and CMMs. These calibrations help maintain fit-for-purpose tolerances, reduce rework, and support quality consistency in food packaging and production lines.

Flow Calibration

We offer flow calibration for liquid and gas flow meters including turbine, Coriolis, and rotameter types. Instruments are verified across multiple flow points to ensure accurate dosing, throughput control, and energy efficiency, all supported by traceable calibration certificates.

Weight Calibration

Our weight calibration services cover scales, balances, and load cells, adjusted using certified mass standards under controlled conditions. Each calibration provides repeatable weighing results crucial for formulation accuracy, packaging precision, and food compliance audits.

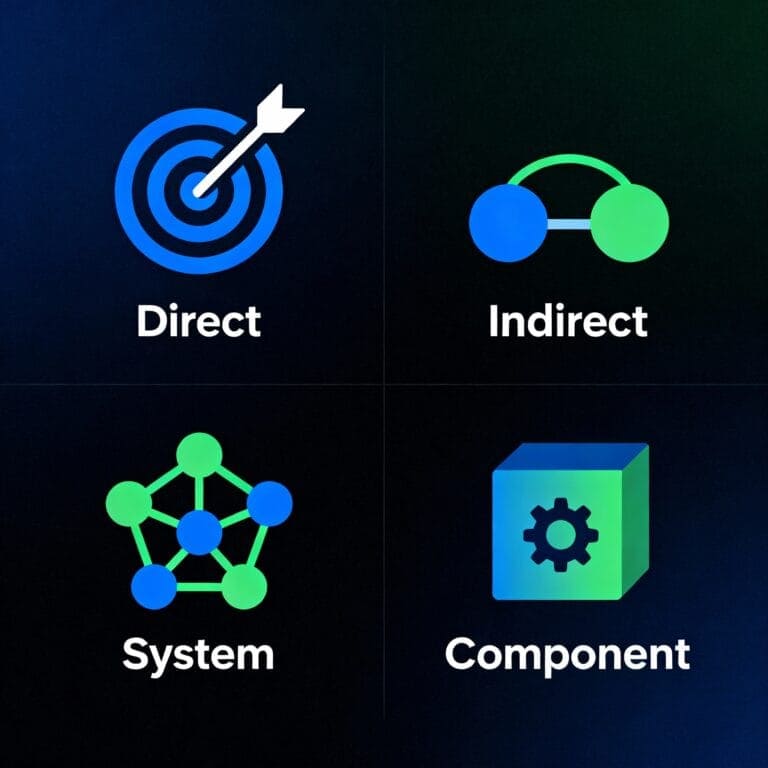

What are Calibration Methods?

At MyFoodExpert, we offer precise calibration services for food industry equipment in India using standardized methods to ensure accuracy, traceability, and compliance.

Direct Calibration

The instrument is compared against a higher-accuracy reference, errors are recorded, and adjustments are made if needed, ensuring reliable instrument calibration for food processing.

Indirect Calibration

Measurements are derived from related calibrated quantities, with uncertainties propagated to guarantee accurate and compliant results.

System Calibration

Entire measurement chains—sensor, wiring, signal conditioning, and software—are calibrated end-to-end, producing a single certificate for complete food lab equipment accuracy.

Component Calibration

Individual components like probes or transmitters are calibrated separately with traceable records, and overall system performance is validated for precision and compliance.

Industry Applications of Our Calibration Services

At MyFoodExpert, we provide comprehensive calibration services for the food industry in India, ensuring that every instrument, sensor, and measurement device functions with certified accuracy and traceability. Our calibration expertise spans across food manufacturing, packaging, laboratories, and cold chain operations, helping businesses maintain compliance with FSSAI, ISO 22000, HACCP, and NABL standards.Below are the key industry applications where our services play a vital role:

1. Food Processing Lines

In food manufacturing and processing environments, even small deviations in readings can lead to significant quality losses. Our calibration services for food processing equipment cover temperature sensors, flow meters, weighing scales, pressure gauges, and control instruments to ensure process parameters remain within defined tolerances.By performing traceable and NABL-aligned calibrations, we help maintain consistent product texture, taste, and safety, ensuring every batch meets your quality benchmarks. Regular calibration improves production efficiency, reduces rework, and guarantees audit-ready measurement records for compliance verification.

2. Laboratory Testing & Quality-Control Labs

Food testing laboratories rely heavily on precision instruments to monitor composition, safety, and compliance. We offer laboratory calibration services for pH meters, moisture analyzers, viscometers, conductivity meters, thermometers, and analytical balances, ensuring reliable test outcomes.Each calibration is performed using certified reference standards with documented measurement uncertainty and traceability to national and international standards. With MyFoodExpert, your lab results remain accurate, reproducible, and defensible during audits or certifications, strengthening your credibility and regulatory compliance.

3. Packaging & Metering Systems

Accurate measurement plays a critical role in packaging, filling, and sealing operations. Our packaging system calibration services include torque wrench calibration, load cell testing, dimension gauge verification, and weighing system calibration to ensure packaging accuracy, material efficiency, and label integrity.Through periodic calibration and preventive verification, MyFoodExpert helps packaging lines reduce material wastage, achieve consistent fill weights, and meet the legal metrology and labeling standards required for food product compliance in India.

4. Cold Storage and Distribution

Temperature control is vital in maintaining food safety throughout storage and transportation. We offer thermal calibration services for temperature sensors, cold chambers, humidity controllers, and data loggers used in cold storage facilities, distribution centers, and reefer vehicles.Our calibration ensures that environmental conditions remain within the required safety ranges, supporting shelf-life validation, FSSAI temperature traceability, and HACCP monitoring. By using NABL-traceable standards, MyFoodExpert guarantees that your calibration results are audit-compliant and globally recognized.

5. Ingredient Formulation & Dosing Systems

Precise ingredient dosing is essential for consistency, flavor, and product integrity in food production. Our weight and flow calibration services for dosing pumps, load cells, batch weighers, and flow controllers help ensure that formulations stay exact, preventing under- or over-dosing.This accuracy enhances recipe consistency, reduces ingredient wastage, and maintains nutritional labeling accuracy — all critical for food labeling compliance and consumer trust. Our calibration certificates document traceable performance verification, supporting your quality assurance and regulatory audits.

Our Calibration Infrastructure & Technology

At MyFoodExpert, we combine advanced calibration infrastructure with cutting-edge technology to deliver high-precision, traceable calibration services for the food industry across India. Our infrastructure is designed to meet international standards of measurement accuracy, supporting clients in achieving full FSSAI, ISO 22000, and NABL compliance while ensuring minimal operational downtime.

“We believe that accurate measurements start with the right environment, tools, and expertise — and our state-of-the-art calibration setup reflects that commitment“.

1. State-of-the-Art Calibration Laboratories

Our calibration laboratories are purpose-built, climate-controlled environments engineered to ensure temperature and humidity stability for accurate and repeatable results. Each lab is equipped with high-accuracy reference standards, traceable to national and international measurement systems (NABL, ISO/IEC 17025).

We perform mechanical, electrical, thermal, flow, and dimensional calibrations under tightly regulated conditions to guarantee consistent measurement accuracy and documented uncertainty. This infrastructure allows food manufacturers, testing labs, and packaging units to depend on our results with full confidence and audit readiness.

2. Portable Calibration Equipment for On-Site Services

Understanding the operational constraints of food businesses, MyFoodExpert also offers on-site calibration services across India. Our portable calibration equipment enables technicians to conduct precise, traceable calibrations directly at your facility — whether it’s a processing unit, testing lab, or packaging line.

This service minimizes equipment downtime while maintaining the same NABL-traceable accuracy you’d expect in a laboratory. We bring calibration of weighing scales, temperature sensors, pH meters, flow meters, and torque wrenches right to your doorstep, ensuring seamless compliance with FSSAI, ISO, and internal audit standards.

3. Skilled and Certified Technical Teams

Our strength lies in our people. MyFoodExpert’s calibration technicians are trained and certified professionals with extensive knowledge of food-industry equipment and regulatory protocols.

Each expert is proficient in the latest calibration methods, including direct, indirect, and system calibration techniques, ensuring every instrument is tested with precision and reliability.

Our teams regularly undergo skill enhancement and standardization training to remain updated with ISO 17025, NABL, and food compliance frameworks, guaranteeing that your calibration services meet the highest global standards.

4. Advanced Digital Calibration Management System

To simplify compliance and documentation, MyFoodExpert provides an online calibration management system that allows clients to:

Schedule and track calibration activities effortlessly.

Access digital calibration certificates with traceable records and uncertainty data.

Receive expiry alerts and upcoming due-date notifications to avoid compliance gaps.

Maintain an instrument calibration history dashboard for easy reference during audits or inspections.

This digital-first approach enhances transparency, ensures data integrity, and supports paperless quality management systems (QMS) for modern food operations.

Frequently Asked Questions (FAQs) – Calibration Services for Food Industry in India

1.What are calibration services for the food industry?

Calibration services for the food industry ensure that equipment such as weighing scales, thermometers, pH meters, and flow meters provide accurate and traceable readings. Regular calibration helps maintain food safety compliance, product quality, and consistency across all processing and testing stages.

2.Why is calibration important in food safety and quality control?

Accurate instruments are essential for maintaining FSSAI and ISO compliance. Regular instrument calibration minimizes measurement errors, reduces wastage, and ensures that food products meet required safety, temperature, and formulation standards.

3.How often should food industry equipment be calibrated?

Most food processing and laboratory instruments should be calibrated every 6 to 12 months, depending on usage and regulatory requirements. MyFoodExpert also provides scheduled calibration plans to help you stay compliant without interruptions.

4.What is NABL-accredited calibration and why does it matter?

NABL-accredited calibration means that the calibration process follows National Accreditation Board for Testing and Calibration Laboratories (NABL) standards. It ensures traceability, international recognition, and accuracy, making your calibration reports valid for audits and certifications.

5.Do you provide on-site calibration services across India?

Yes. MyFoodExpert offers both on-site and in-lab calibration services for food industry clients across India. Our technicians use portable reference instruments to perform precise, traceable calibrations at your facility, minimizing downtime.

6.What types of instruments can MyFoodExpert calibrate?

We calibrate a wide range of instruments used in food production and testing, including mechanical, electrical, thermal, dimensional, flow, and weight equipment. Each calibration is performed using NABL-traceable standards and includes a calibration certificate with uncertainty data.

7.What is the difference between direct and indirect calibration?

In direct calibration, the instrument is compared directly to a higher-accuracy reference, while indirect calibration determines results using related measured quantities like voltage or current. Both methods provide traceable and verifiable results depending on the instrument type.

8.How does calibration improve food industry compliance?

Proper calibration ensures that every reading from your food processing and lab instruments is reliable and within tolerance. This helps your business stay compliant with FSSAI, ISO 22000, HACCP, and NABL requirements while maintaining product integrity and consumer trust.

9.Will I receive a calibration certificate after service?

Yes. Every service includes a detailed calibration certificate specifying the instrument details, traceable references, uncertainty levels, and results. This documentation supports audit readiness and ongoing quality management.

10.How can I book calibration services with MyFoodExpert?

You can easily request calibration services online through our contact form or by calling our team. We’ll schedule your service, confirm the instruments to be calibrated, and ensure quick turnaround with NABL-traceable results.

11.What makes MyFoodExpert’s calibration infrastructure unique?

MyFoodExpert’s calibration infrastructure stands out because it combines state-of-the-art laboratories, climate-controlled testing environments, and NABL-traceable reference standards. Every calibration is conducted in accordance with ISO/IEC 17025 protocols to deliver accurate, reliable, and compliant calibration services for the food industry in India. This ensures your instruments meet global measurement standards while remaining fully audit-ready.

12.How does NABL-traceable accuracy improve calibration quality?

Our NABL-traceable calibration process ensures that every measurement result is linked to recognized national and international standards. This traceability guarantees measurement consistency, reduced uncertainty, and regulatory acceptance during audits. For food manufacturers, it means your equipment calibration meets FSSAI, ISO 22000, and HACCP compliance requirements, ensuring quality assurance and confidence in every test.

13.What types of calibration capabilities does MyFoodExpert offer?

We provide full-spectrum calibration services covering temperature, thermal, flow, electrical, mechanical, and dimensional instruments — all under one roof. Whether you require calibration for weighing scales, sensors, torque wrenches, flow meters, or pH meters, our advanced infrastructure and portable on-site systems deliver precise results backed by NABL and ISO 17025 traceability.

14.Does MyFoodExpert offer on-site calibration services across India?

Yes. MyFoodExpert offers nationwide on-site calibration services for food industry clients across India. Our mobile calibration units and expert technicians can perform accurate, traceable calibration directly at your facility — reducing downtime and ensuring continuous production compliance. This flexibility allows food manufacturers, laboratories, and packaging units to stay audit-ready without interrupting daily operations.

15.How does MyFoodExpert ensure audit-ready calibration documentation?

Every calibration performed by MyFoodExpert includes a comprehensive calibration certificate that specifies the instrument details, reference standards, measurement uncertainty, and traceability. These certificates comply with FSSAI, ISO 22000, and HACCP audit requirements and can be accessed digitally through our online calibration management system. This ensures your calibration records remain organized, verifiable, and instantly available for any inspection.