FSSAI Internal Audit Service for Food Businesses – Ensure Complete Food Safety Compliance

Regular FSSAI internal audits help food businesses identify compliance gaps, strengthen food safety systems, and stay audit-ready.

MyFoodExpert’s team of certified auditors ensures your operations, documentation, and hygiene practices fully meet FSSAI and ISO 22000 requirements.

At MyFoodExpert, our certified food safety professionals conduct detailed audits that cover hygiene, processing controls, and record-keeping to ensure your business aligns with FSSAI regulations and ISO 22000 food safety management requirements. We help you stay inspection-ready, prevent penalties, and strengthen your brand’s credibility in the food industry.

What Is an FSSAI Internal Audit?

An FSSAI internal audit is a systematic evaluation of your food safety management system to verify compliance with FSSAI standards.

It involves reviewing your processes, documentation, hygiene practices, and control measures to identify non-conformities before external inspections.

Why FSSAI Internal Audit Is Important for Food Businesses

Running a food business in India means adhering to the strict safety and hygiene standards mandated by the Food Safety and Standards Authority of India (FSSAI). Conducting a regular FSSAI internal audit is not just a compliance formality—it’s a strategic step toward ensuring long-term food safety, operational efficiency, and brand trust. Here’s why every food business should prioritise it:

1. Ensures Continuous FSSAI Compliance and Audit Readiness

A well-structured FSSAI internal audit helps you verify that all your processes, documents, and hygiene practices are fully aligned with FSSAI guidelines.

It ensures that your business remains audit-ready at any time, reducing the stress and risk of non-compliance during inspections by food safety officers or certification bodies.

2. Identifies Non-Conformities and Areas for Improvement

Through systematic evaluation, internal audits pinpoint non-conformities in your food safety management system — whether it’s in documentation, production hygiene, or staff training.

Identifying these gaps early allows your business to take corrective and preventive actions (CAPA), improving operational efficiency and maintaining compliance continuity.

3. Reduces Risk of Product Recalls, Penalties, and Legal Issues

Neglecting internal audits can expose your business to severe risks — contaminated batches, failed inspections, or even license suspension.

By conducting periodic FSSAI internal audits, you minimize the chance of product recalls, reduce penalty risks, and demonstrate your brand’s commitment to food safety and consumer protection.

4. Enhances Food Safety Culture and Staff Accountability

Internal audits are more than checklists — they promote a culture of food safety awareness across all levels of your organization.Audits educate your employees about hygiene protocols, critical control points, and FSSAI documentation standards, making every team member responsible for maintaining safety.

5. Builds Consumer and Regulatory Trust

Consistent internal auditing showcases your brand’s dedication to food quality and transparency.

When your processes are regularly audited and documented, both customers and regulatory authorities view your business as reliable and compliant.This not only strengthens your reputation but also provides a competitive advantage in an increasingly regulated food industry.

A thorough FSSAI internal audit is the backbone of a com`pliant and trustworthy food business.

It protects your operations from non-compliance risks, boosts confidence during regulatory audits, and demonstrates your commitment to food safety excellence.

What Is Checked in an FSSAI Internal Audit?

A FSSAI internal audit is a comprehensive evaluation of all activities, records, and hygiene practices that affect food safety and regulatory compliance.It helps food businesses identify risks, improve systems, and ensure full FSSAI compliance before any external inspection or certification audit.Below is a detailed look at what a typical FSSAI internal audit checklist covers:

1. Premises and Plant Hygiene

Auditors inspect the overall cleanliness and layout of the premises, ensuring compliance with FSSAI Schedule 4 guidelines.

They check building design, ventilation, drainage, lighting, and waste disposal systems to ensure your facility maintains a hygienic food production environment.

2. Raw Material Handling and Storage

Proper handling and storage of ingredients is vital to prevent contamination.

During the FSSAI internal audit, auditors review how raw materials are sourced, labelled, and stored — including temperature control, FIFO (First In, First Out) system, and segregation of allergens.

3. Good Manufacturing Practices (GMP)

Your production line is assessed for adherence to GMP and GHP (Good Hygiene Practices) standards.

This includes equipment cleanliness, preventive maintenance, calibration, and process control to ensure consistent food quality and safety.

4. Pest Control and Sanitation

The internal audit examines the effectiveness of your pest control program — frequency, documentation, and type of pesticides used.

Auditors also verify your cleaning and sanitation schedules, ensuring all areas, utensils, and machinery meet FSSAI hygiene standards.

5. Employee Hygiene and Training

Personnel hygiene is a key element of the FSSAI internal audit checklist.

Inspectors verify that all staff follow proper hygiene practices such as wearing protective clothing, maintaining hand hygiene, and attending food safety training programs regularly.

6. Labeling, Packaging, and Traceability

Auditors check whether your product labels comply with FSSAI labeling regulations, including allergen information, batch numbers, and expiry dates.

They also verify packaging integrity and traceability systems to ensure every product can be traced from raw material to consumer delivery.

7. Review of FSMS Documentation and SOPs

A critical part of the internal audit involves evaluating your Food Safety Management System (FSMS) documentation.

Auditors review SOPs (Standard Operating Procedures), monitoring records, calibration logs, and corrective action reports to confirm compliance with FSSAI and ISO 22000 standards.

Completing a detailed FSSAI internal audit checklist prepares your business for any third-party food audit, ISO certification, or regulatory inspection by FSSAI authorities.

It ensures your food business remains compliant, consistent, and credible — ready to meet national and global food safety standards.

How Often Should FSSAI Internal Audits Be Conducted?

To maintain strong FSSAI compliance and a proactive food safety culture, every food business operator (FBO) should conduct internal audits at least twice a year. These audits ensure continuous monitoring of hygiene practices, documentation accuracy, and compliance with Food Safety Management System (FSMS) requirements.For high-risk food categories such as dairy, meat and poultry, bakery, and ready-to-eat (RTE) food products, it is recommended to perform quarterly FSSAI internal audits. This frequent review helps identify non-conformities early, address potential hazards, and maintain operational excellence before any external FSSAI or third-party food safety inspection.

In today’s dynamic food industry, routine FSSAI internal audits are not just about regulatory adherence — they play a vital role in building consumer trust, ensuring food hygiene, reducing the risk of legal penalties, and preventing business disruptions.Adopting a risk-based audit frequency aligned with your production processes and category-specific risks is the smartest way to ensure continuous FSSAI audit readiness and protect your brand reputation in 2025 and beyond.

Benefits of Conducting FSSAI Internal Audits

Conducting regular FSSAI internal audits is one of the most effective ways for food businesses to maintain consistent food safety, operational efficiency, and brand trust. These audits act as a preventive and corrective tool that ensures your facility complies with FSSAI regulations and international food safety standards like ISO 22000 and HACCP.Here are the key benefits of performing routine internal food audits:

1.Minimize the Risk of Food Contamination

Internal audits help detect hygiene lapses, equipment issues, and unsafe handling practices before they escalate, reducing the risk of contamination and product recalls.

2.Ensure Continuous Regulatory Compliance

Regular internal audits ensure your business stays compliant with FSSAI guidelines, documentation protocols, and inspection readiness, preventing legal penalties and license suspension.

3.Enhance Product Quality and Hygiene Standards

By reviewing Good Manufacturing Practices (GMP) and sanitation controls, internal audits improve production quality, shelf-life, and overall product consistency.

4.Build Brand Trust and Customer Confidence

Consumers trust brands that prioritize food safety compliance. Regular internal audits showcase your commitment to hygiene, transparency, and accountability.

5.Stay Prepared for FSSAI and Third-Party Audits

Routine internal reviews ensure your team, documentation, and systems are always ready for FSSAI inspections, ISO audits, or certification renewals — without last-minute stress.

In short, FSSAI internal audits are not just about compliance — they’re about creating a safety-driven, quality-focused culture that protects your consumers and strengthens your brand’s reputation.

In short, FSSAI internal audits are not just about compliance — they’re about creating a safety-driven, quality-focused culture that protects your consumers and strengthens your brand’s reputation.

FAQ's

Q1: What is internal auditing in FSSAI?

A: Internal auditing in FSSAI is a structured self-assessment process conducted by food businesses to evaluate compliance with food safety regulations, hygiene standards, and documentation requirements under the Food Safety and Standards Act. It helps identify gaps in operations and ensures continual FSMS (Food Safety Management System) improvement.

Q2: Is internal audit mandatory for food businesses under FSSAI?

A: While not always legally mandatory, FSSAI internal audits are strongly recommended — especially for licensed manufacturers, high-risk categories like dairy, meat, or bakery products, and export units. Many ISO and HACCP-certified facilities make internal audits a mandatory part of certification maintenance.

Q3: How often should internal audits be done?

A: As per FSSAI best practices (2025), internal audits should be conducted at least twice a year. However, high-risk food categories should undergo quarterly audits to ensure consistent FSSAI compliance, hygiene monitoring, and audit readiness.

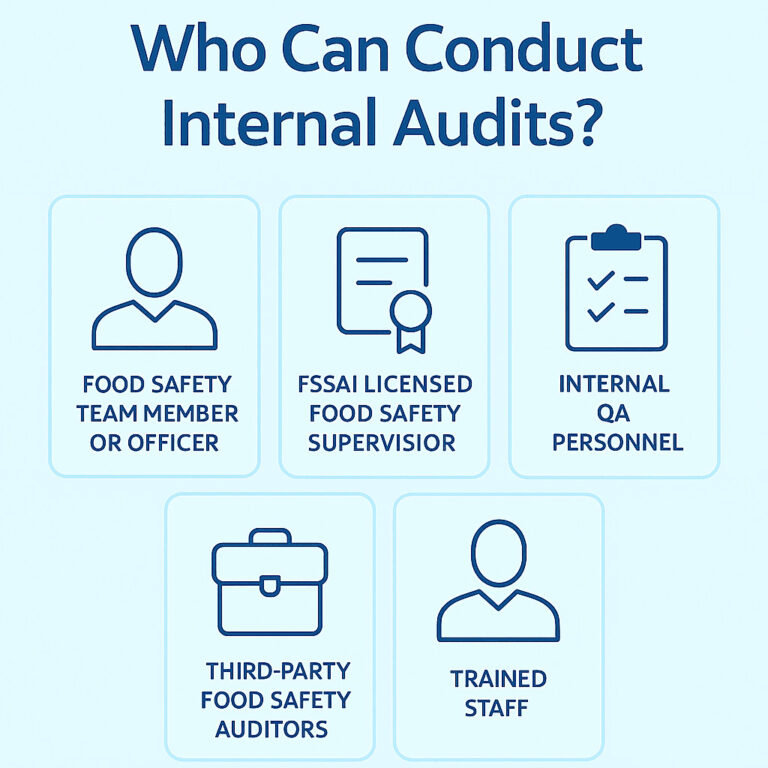

Q4: Who can conduct an internal food audit?

A: Internal audits can be carried out by a trained Food Safety Supervisor (FoSTaC certified), an internal quality assurance team, or an external FSSAI-approved food safety consultant. The key is that the auditor must be competent, unbiased, and familiar with FSSAI regulations.

Q5: What is included in an FSSAI internal audit checklist?

A: A standard FSSAI internal audit checklist covers:

- Premises and plant hygiene

- Employee hygiene and training

- Raw material handling and storage

- Labeling and packaging compliance

- SOP and FSMS documentation

- Sanitation and pest control measures

These checkpoints ensure thorough preparation for third-party audits or FSSAI inspections.

Q6: What are the benefits of conducting internal audits?

A: Regular internal audits help:

- Maintain continuous FSSAI compliance

- Prevent food contamination

- Improve operational efficiency

- Avoid legal penalties and non-conformities

- Strengthen consumer trust and brand image

Q7: Can small food businesses skip internal audits?

A: Even small FBOs (Food Business Operators) should conduct internal audits. They help detect issues early, improve food handling practices, and maintain basic FSSAI compliance, especially for businesses planning to expand, export, or obtain higher certifications.

Q8: How do internal audits support FSSAI inspections?

A: Internal audits act as a rehearsal for FSSAI inspections. They ensure your facility’s hygiene, records, and processes are compliant and up-to-date, minimizing the risk of non-compliance reports, penalties, or operational disruptions.

Q9: What is the main purpose of an FSSAI internal audit?

A: The main purpose of an FSSAI internal audit is to verify that a food business follows all food safety protocols, hygiene practices, and documentation requirements. It ensures compliance with FSSAI, ISO 22000, and HACCP standards while identifying non-conformities before official inspections.

Q10: What documents are required during an FSSAI internal audit?

A: Common documents required include:

- FSSAI license copy

- FSMS plan and SOPs

- Sanitation and pest control records

- Employee training logs

- Supplier and raw material records

- Equipment cleaning and calibration reports

Maintaining updated records helps ensure a smooth internal audit process and FSSAI compliance.

Q11: How can a food business prepare for an FSSAI internal audit?

A: To prepare effectively, food businesses should review their FSMS documentation, conduct a mock audit, ensure cleanliness and hygiene compliance, verify traceability records, and train staff on FSSAI guidelines. Preparation ensures the audit runs efficiently and without non-conformities.

Q12: What are common non-conformities found during internal audits?

A: Frequent issues include improper hygiene, missing calibration logs, outdated records, lack of pest control evidence, poor labeling, and untrained staff. Addressing these proactively through regular FSSAI internal audits prevents regulatory penalties.

Q13: What’s the difference between an internal audit and a third-party audit?

A: An internal audit is conducted by your in-house team or consultant to assess compliance readiness, whereas a third-party audit is performed by an external certification or FSSAI-approved agency for official compliance verification.

Q14: How does FSSAI internal auditing improve operational efficiency?

A: Internal audits streamline food production by identifying process inefficiencies, improving documentation accuracy, and ensuring Good Manufacturing Practices (GMP) are consistently followed — resulting in smoother operations and reduced wastage.

Q15: Can internal audits help with ISO or HACCP certification?

A: Yes. Regular FSSAI internal audits align closely with ISO 22000 and HACCP principles. They help businesses maintain consistent documentation, risk assessment, and control measures required for global food safety certifications.

Q16: What happens after an internal audit is completed?

A: After the audit, the auditor provides a detailed report highlighting non-conformities and improvement areas. The management team must take corrective and preventive actions (CAPA) to close the gaps before the next FSSAI or third-party inspection.

Q17: How can technology help in FSSAI internal audits?

A: Using digital audit tools or FSSAI compliance software simplifies record-keeping, generates instant audit reports, tracks corrective actions, and ensures continuous compliance — reducing manual effort and audit time.

Q18: What is the penalty for non-compliance after an internal audit?

A: If non-conformities are not corrected, businesses risk license suspension, fines, or closure under FSSAI regulations. Conducting regular internal audits helps prevent these issues by ensuring ongoing compliance and readiness for official inspections.